Providing high-performing current profiling for oil and gas production in Brazil

- User stories

SLI Coastal Solutions in Brazil provides metocean instrumentation and measurements for ports, as well as for coastal and offshore projects.

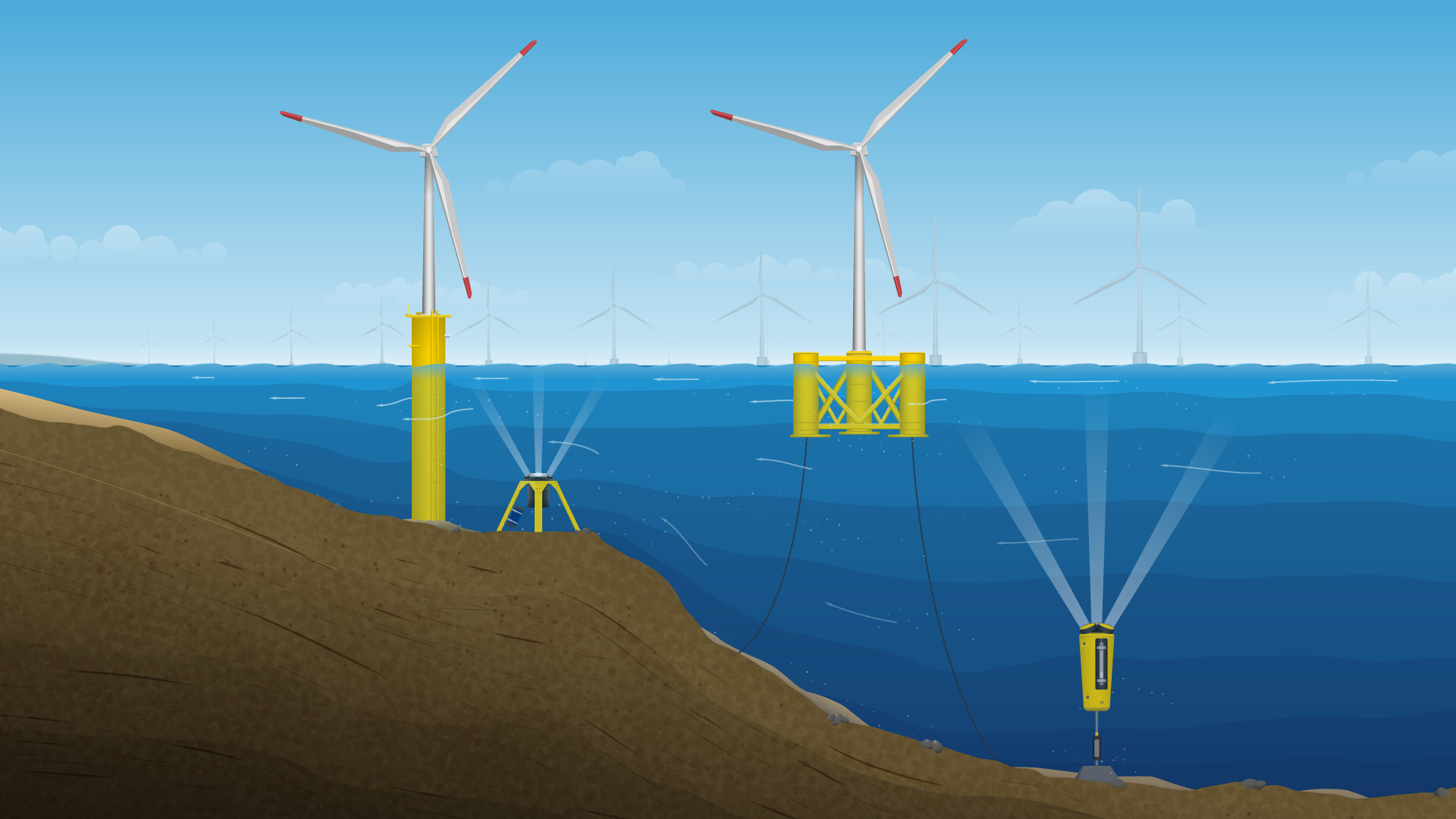

One of their clients was already using a 38 kHz current profiler (ADCP) on their Floating Production Storage and Offloading (FSPO) facility, but needed a longer current profiling range. Their client therefore requested a practical test with Nortek’s Signature 55 to compare this ADCP to their existing instrumentation.

“Our client’s intention was to achieve a longer profiling range – initially beyond 600 m, and eventually reaching 1000 m. As a test, they installed a Signature 55 on an FPSO,” says Leandro Franklin, Chief Operating Officer at SLI Coastal Solutions. Franklin has over 20 years of professional experience related to operational oceanography, environmental monitoring, management and execution of projects related to oil and gas, mining and ports.

A Floating Production Storage and Offloading (FPSO) unit is a floating vessel used by the offshore oil and gas industry for the production and processing of hydrocarbons, and for the storage of oil.

Seamless integration

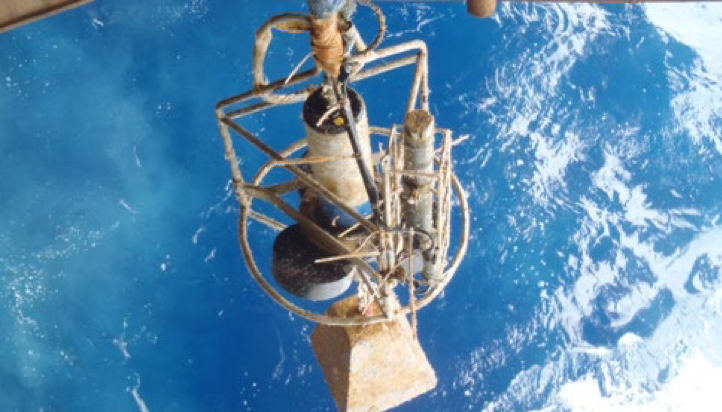

The FPSO vessel in question here was already equipped with a winch to deploy the ADCP, so the only upgrades required to the existing infrastructure were to an additional instrument deployment cage and cables. An Aquadopp ADCP was deployed at the same time to measure surface currents near the FPSO.

“The integration of the Signature 55 with the main computer was an easy task, and the process was seamless thanks to the simple user interface and hardware,” reports Franklin. “By combining the knowledge of SLI Coastal Solutions, Nortek and the client’s technicians, we succeeded in integrating the measurements from the Signature 55 and Aquadopp ADCPs into the Metocean Information System, which up until now was set up to only operate with competing ADCP brands. The DADAS software (from A+D) was utilized for this deployment,” he adds.

High performance throughout three years’ deployment

The system was deployed and operated for almost three consecutive years, located about 20 m below the water surface. The water depth at the location of the FPSO was more than 1500 m. Preventive maintenance was undertaken every three months to combat biofouling and to test specific components prior to redeployment.

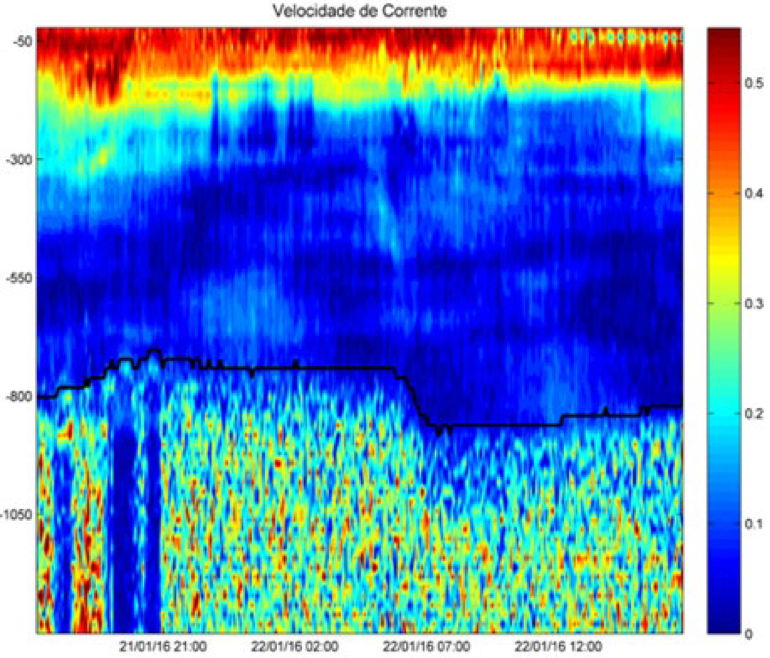

“The maximum range oscillated between 750 and 850 m. The client configured the Signature 55 to provide current profiles up to 750 m to ensure that they could obtain a continuous time series of the highest resolution,” Franklin explains. “At this range the Signature 55 had great performance throughout the whole deployment, even with the acoustic and structural complexities of an oil and gas production field,” he adds.

Robust and easy to operate

In terms of maintenance and robustness, no inconsistencies or problems were detected over the course of the three-year deployment, apart from four oxidized screws surrounding the connector. At the end of the deployment, the screws were replaced with an alloy that is not prone to oxidation. Given that the deployment was three years long, this issue was negligible.

“Our experience with the use of the Signataure 55 as a long-range current profiler in the demanding oil and gas market was that the instrument was easy to operate, robust and small enough for a two-person crew to deploy and service,” Franklin says.

He emphasizes that the Signature 55 performed flawlessly for three years, with no problems related to communication, data collection or corrosion in the housing/transducers.

“We now include this instrument as the preferred ADCP for oil and gas projects of this nature. We prefer the Signature 55 because it allows us to keep our operational index at the highest possible level within the oil and gas market,” Franklin concludes.