Multi-functional navigation sensor benefits micro-AUV operations

- User stories

Synopsis

Challenge

RTsys required a sensor for their NemoSens® micro-AUV which would not only contribute to vehicle navigation, but also collect current profiles.

Solution

The compact Nucleus 1000 fit the small footprint of the micro-AUV while simultaneously offering navigation information as well as current profiling.

Benefit

The simple integration of a single sensor for multiple purposes enables the NemoSens to maintain its small footprint while navigating and collecting data.

RTsys: AUVs and more

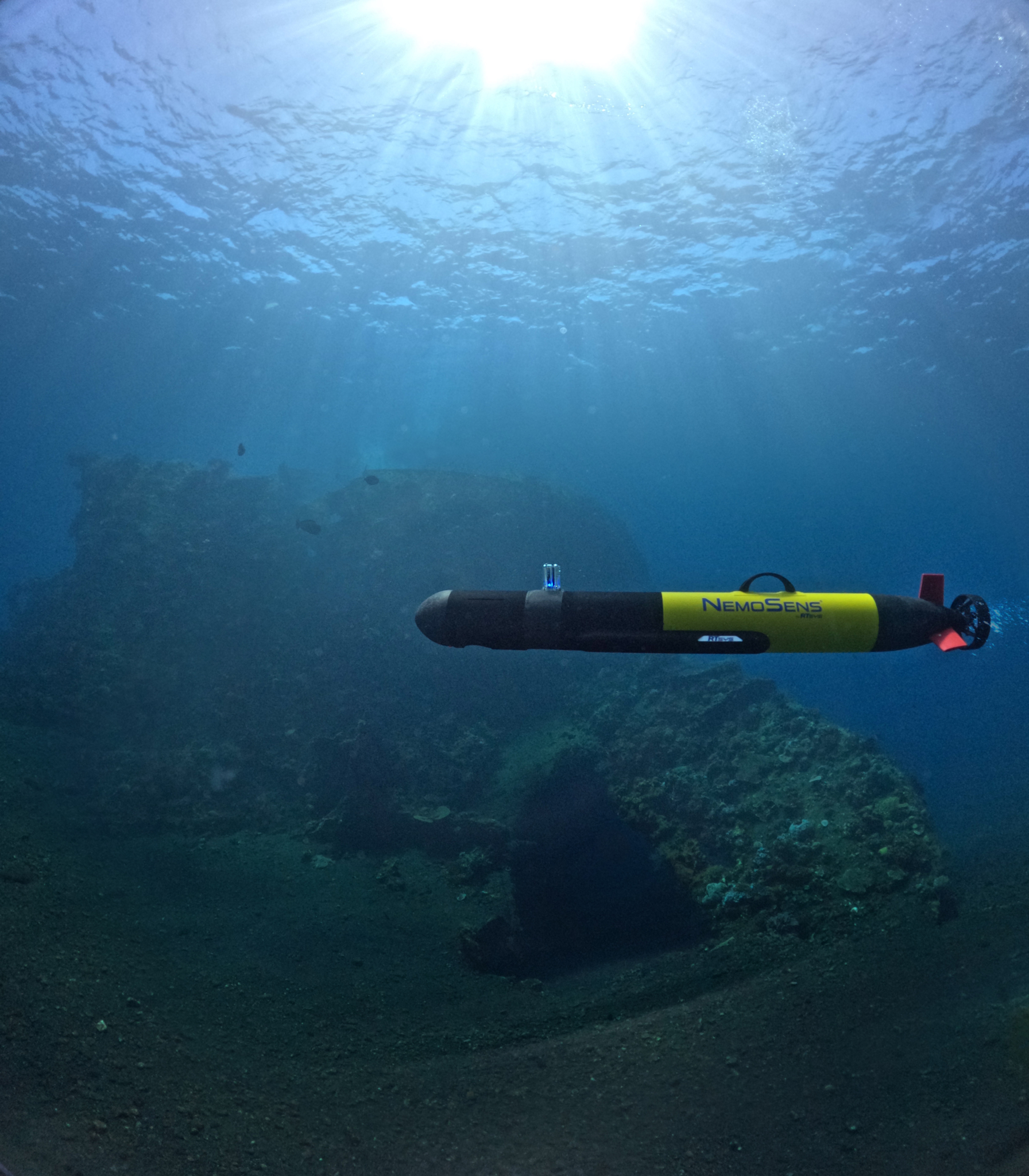

French company RTsys specializes in underwater acoustics and autonomous underwater vehicles (AUVs). They work on a range of applications including passive acoustic monitoring, mine countermeasures and anti-submarine warfare. AUVs are a crucial part of these applications, as they offer a safe and effective way to explore the subsea environment without human risk.

RTsys offers three AUVs: the SEMA, the COMET-300 and the NemoSens®. All AUVs offer high levels of capability but are small and easily deployable. In the rapidly growing world of rapidly shrinking subsea vehicles, the ability to deploy easily and inexpensively is key.

The benefits of a micro-AUV

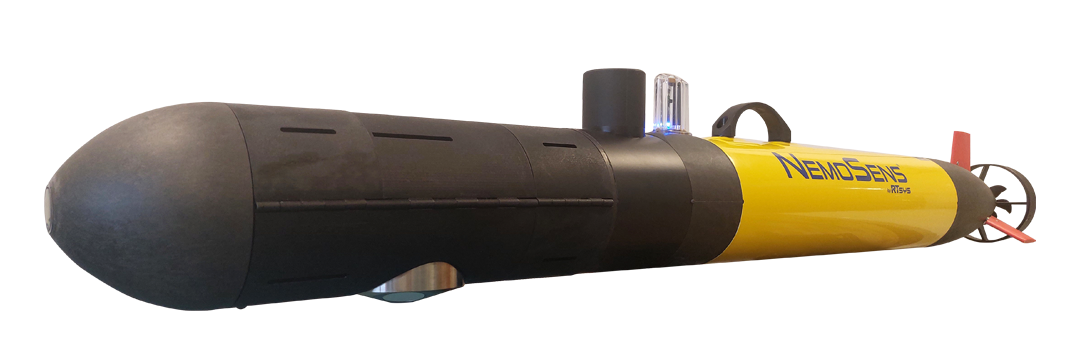

The NemoSens micro-AUV is deployable by a single person from a small boat. It’s smaller than a piece of carry-on luggage and weighs less than 10 kg: less than a 24-pack of soda. Despite their small size, micro-AUVs enable large-scale data collection. The NemoSens is rated to 300m depth and can perform missions lasting up to 10 hours.

Small vehicle footprints demand compact and space-efficient sensors to maximize vehicle capabilities without compromising on size and weight.

“We implement lots of payloads. That could be a side scan sonar, video camera, magnetometer, CTD and various multi-parameter probes, and most importantly a DVL,” says Cyrille Lohier, AUV Product Manager Science & Industry at RTsys.

When RTsys needed to tackle a customer project requiring not only the ability to accurately navigate the NemoSens but also the collection of current profiles from the micro-AUV, the Nucleus 1000 from Nortek offered a multi-functional, compact sensor solution.

Monitoring currents from an AUV during dredging

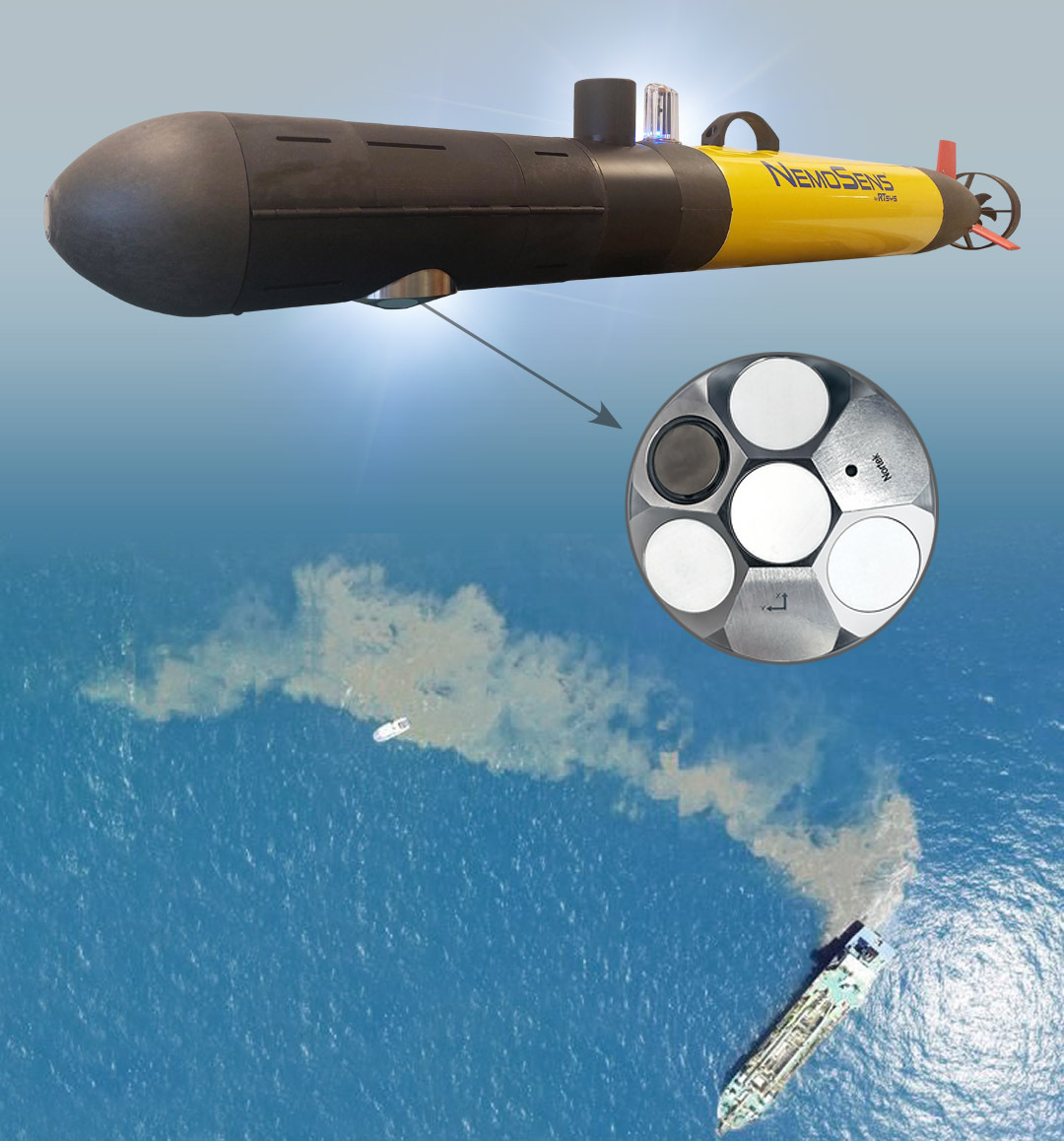

The project which spurred the integration of the Nucleus with the NemoSens AUV was requested by one of RTsys’ customers, a leading European dredging company. According to Lohier, the company wanted to use the AUVs to ensure that sediments would not be moved too far from their original position after dredging operations were complete. Typically, this is achieved by taking measurements from buoys stationed every 500m from the dredging site to monitor the amount of sediments being displaced.

However, the company wanted more information than could be provided from relatively faraway, stationary buoys. They wanted to use NemoSens AUVs, operating at multiple different altitudes, to survey the area from the dredging site to the buoy with the goal of monitoring the sediment plume during dredging operations.

“Our customer wanted to characterize the plume movements, given the currents,” explains Lohier. “They said to us they wanted a dynamic solution with a turbidity sensor, as well as a DVL with current profiling capability.”

Underwater navigation and current profiling from one sensor

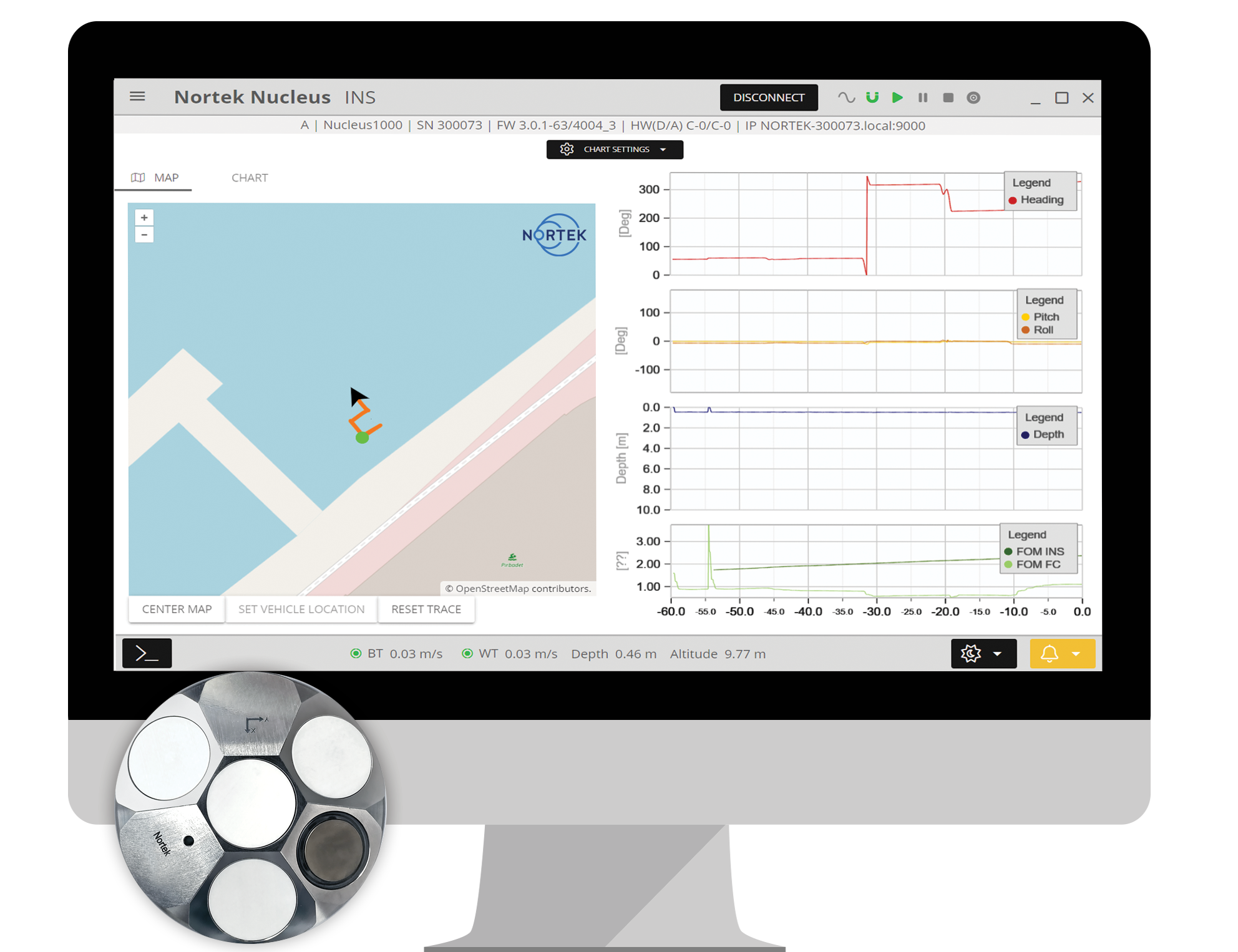

The Nucleus 1000 fit the bill for the requests of this project. Designed for very small AUVs like the NemoSens, the Nucleus combines multiple functionalities into a single compact sensor. It offers DVL capabilities with a pre-integrated AHRS or INS (license-dependent). This means small vehicle users can use this single sensor to achieve true navigation, without requiring the extra steps such as integration and calibration normally required to pair a DVL and INS.

The Nucleus is also unique among similar small DVLs in its ability to collect current profiles. This added benefit was crucial to this dredging project and can also benefit many other AUV operations.

Positive collaboration for successful Nucleus integration

Nortek worked with RTsys on the integration of the Nucleus on the NemoSens for this project. It was the first time RTsys had integrated the Nucleus on their vehicle, but Lohier says the process was smooth thanks to the help from Nortek.

“The collaboration with Nortek was really good from the beginning,” says Lohier. “Nortek was very reactive to our demands. They were also very proactive with helping us integrate the system.”

According to Lohier, the results were from the Nucleus on the NemoSens were also just as they had hoped, and the short lead times for the Nucleus were an added bonus.

“We are really happy with the results from the Nucleus. The performance is really good,” says Lohier. “The data were really accurate, the software integration was simple. [It is a] big satisfaction for us to have integrated that DVL.”

Looking forward, Lohier is optimistic about the possibilities of using the Nucleus 1000 on the NemoSens for a variety of AUV missions in the future.