Providing current and wave data to the offshore wind energy industry

- User stories

Synopsis

Challenge

Metocean survey company Partrac Ltd needed to characterize currents and waves at a deepwater site to determine suitability for an offshore floating wind turbine.

Solution

The team used a Signature 250 ADCP on a subsurface buoy to gather current and wave data up to 150 m depth.

Benefit

The long-range capability of the Signature 250 provided Partrac with a cost-effective solution to characterize conditions in deeper waters offshore.

As the world seeks to meet increasingly ambitious net-zero carbon emissions targets, the need for expansion in the offshore wind sector is clear. Energy generation capacity was forecast to increase eightfold, from 29.1 gigawatts (GW) in 2019 to more than 234 GW in 2030, according to the Global Wind Energy Council (GWEC).

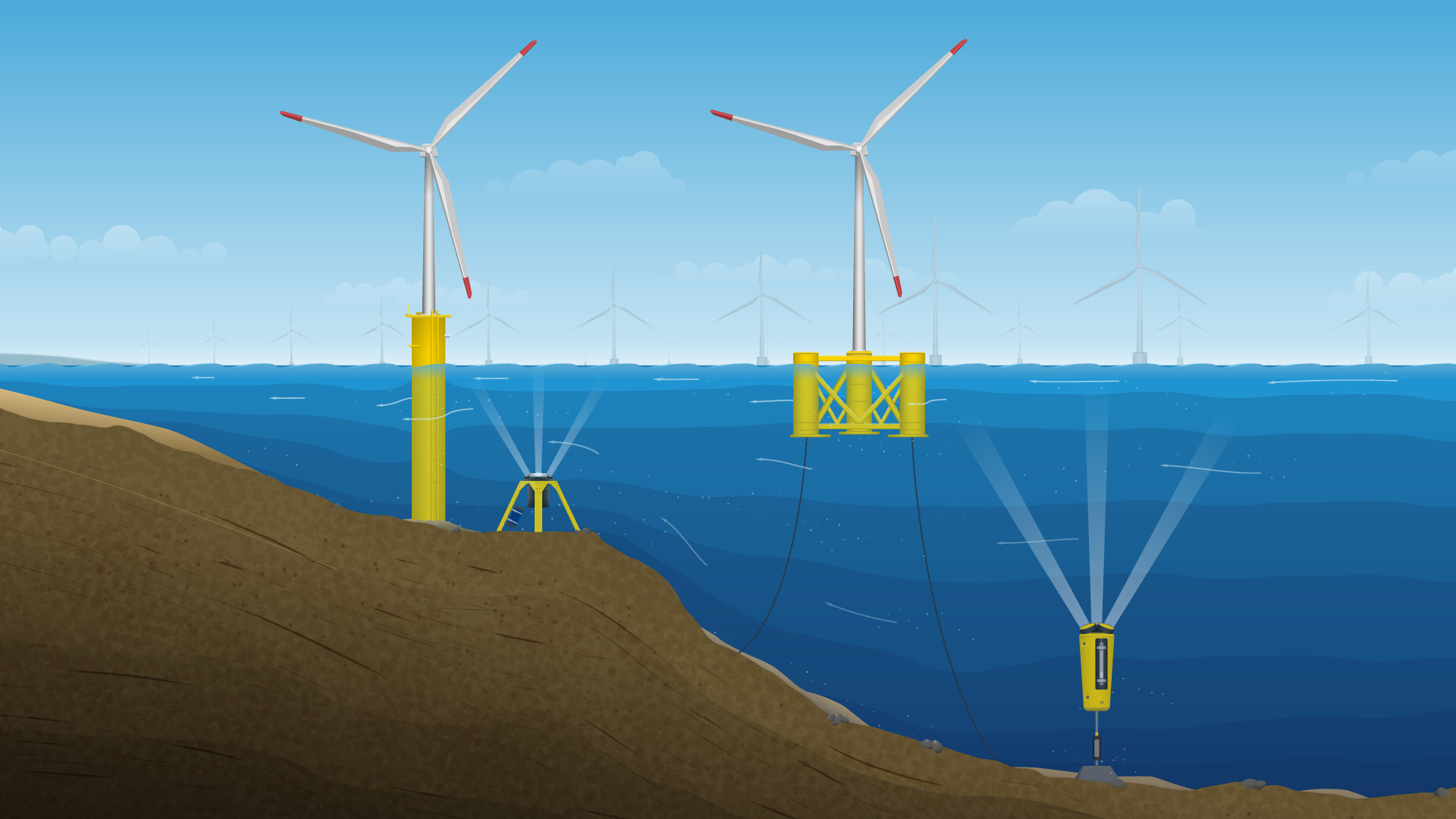

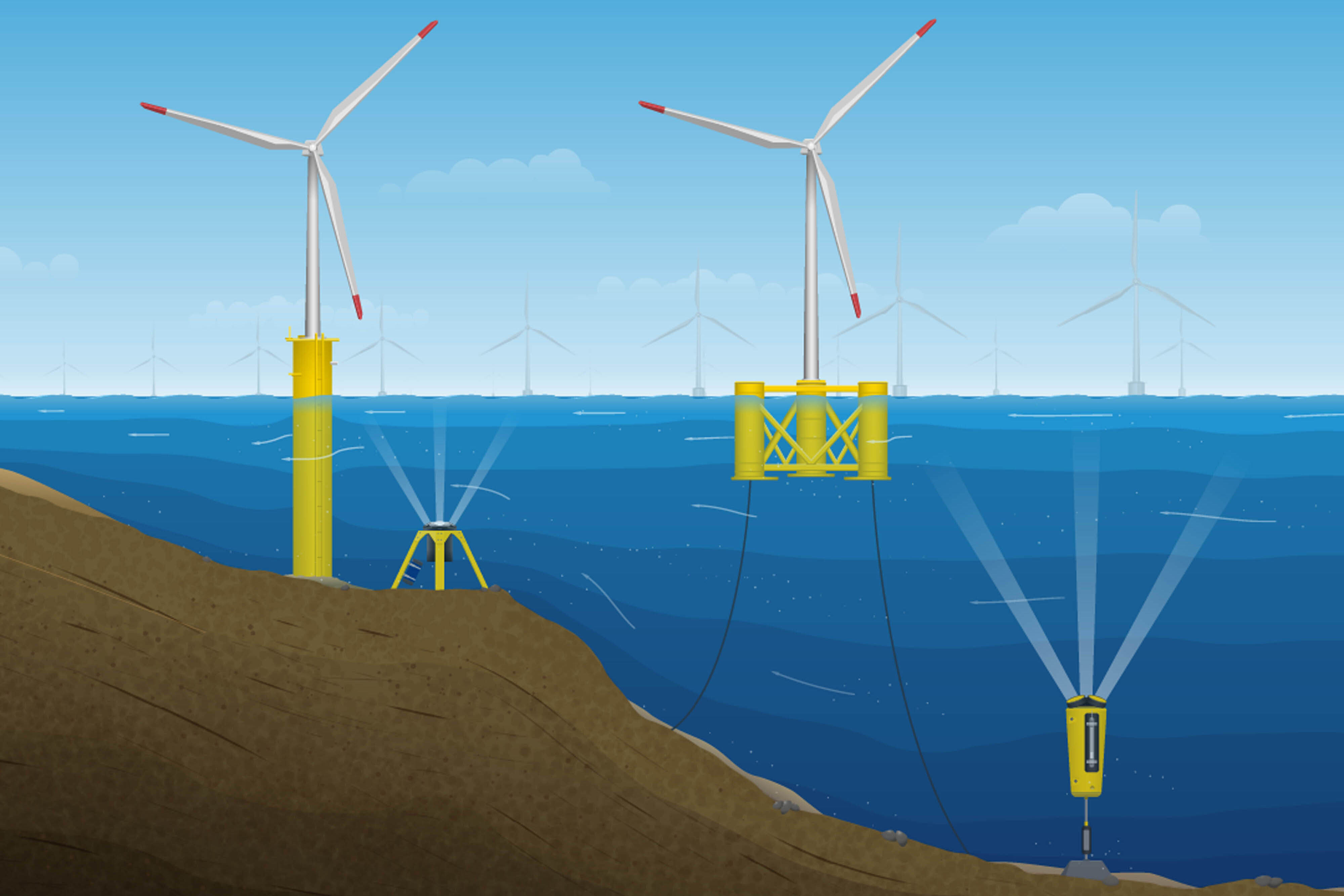

Thus far, virtually all offshore wind energy produced globally has come from turbines located in water shallower than 50 m, where the turbine tower can be directly attached to the seabed. But with demand for wind power growing fast – and suitable shallow-water sites filling up in some places – the industry is now seeking to move into deeper water. However, these environments create a new set of challenges for developers.

Existing monopile or gravity designs typically used for shallow-water windfarms, which involve attaching the tower directly to the seabed, are not as simple or cost-effective to deploy in deep water. As seen in other industries, it can be more cost-effective and practical for deep-water wind turbines to be located on floating structures tethered to the seabed, potentially opening up a lot more of the ocean to windfarm developments.

Despite the advantages of using floating platforms, offshore wind developments remain complex, so obtaining the most accurate data on the metocean conditions at proposed sites is crucial. The wind resource may be plentiful, but ocean conditions in deeper water provide a different set of challenges from those in shallow waters close to shore – and they require different tools and expertise to analyze them.

Robust, longer-range ADCPs for deep-water offshore wind energy sites

For Partrac, one of the UK’s leading metocean survey and geoscience consultancy providers, the rising interest in floating offshore windfarms means the company is increasingly being asked to obtain data that developers can use for site characterization and modeling in deeper water than the norm.

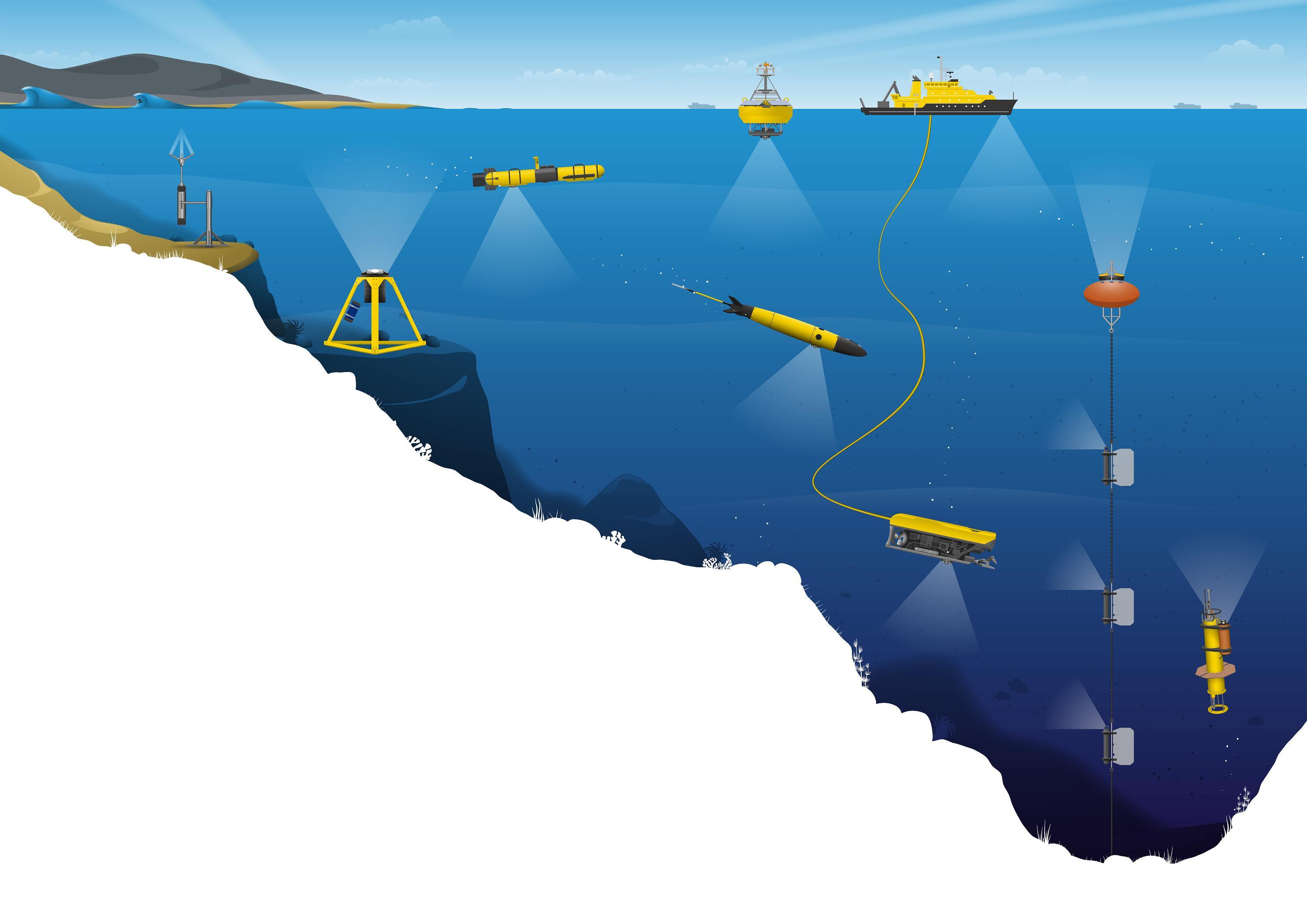

ADCPs have long been a crucial part of Partrac’s toolkit for constructing detailed profiles of current and wave movements around windfarms. These instruments provide highly accurate profiles of water movement using the Doppler effect to measure the shift in sound waves reflected from particles at various depths through a water column; crucially they are also able to measure the wave climate.

But moving to deeper water now requires a longer-range ADCP solution.

Partrac deploys the Signature 250 long-range ADCP for offshore wind energy studies

The Nortek team has been well placed to help with this shift, having provided ADCPs and expertise to Partrac over many years.

Historically, shallow-water wind farm feasibility studies have been carried out using Nortek’s higher-frequency, shorter-range Signature and AWAC instruments. But collecting data in deeper waters requires equipment designed to withstand, and measure, extreme wave regimes, while accurately measuring currents from surface to near seabed across a greater depth.

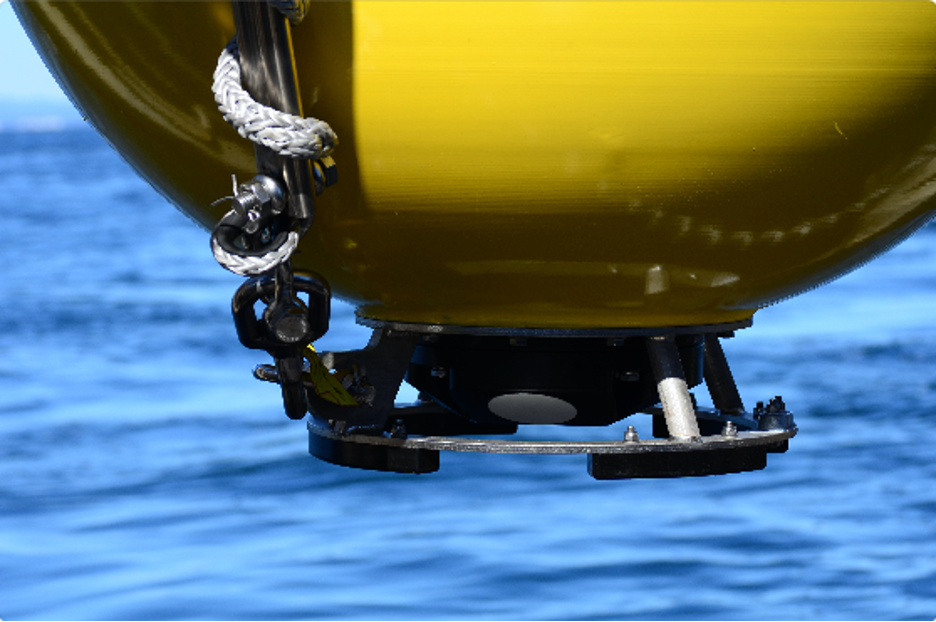

With these challenges in mind, Nortek was able to provide Partrac with its Signature 250 ADCP and accompanying subsurface buoy. The instrument allows users to measure currents and directional waves up to 200 m for current profiling, and 150 m for wave height and direction, making it the preferred choice for deeper-water wind turbine sites.

“We needed an instrument for deeper water that could still measure both current profiles and the wave climate. The Signature 250 has proven to provide exceptional data thus far,” says Pete Wilson, Operations Director at Partrac.

“We also purchased the new Nortek buoy system to house the instrument, and this has proven to be a valuable addition to our fleet of mooring solutions. We needed it quite quickly and Nortek were able to deliver within our time constraints,” he adds.

When deploying with Nortek’s subsurface buoy, users have the option of housing both the instrument and an external battery canister within the same flotation device. This novel solution is a neat, robust and compact approach that simplifies the mooring design and facilitates deployment in a wider range of sea conditions.

High-quality ADCPs, progressive approach and responsive service

Nortek’s commitment to responsive service, quality and innovation has underpinned the relationship between the two companies. “We choose Nortek instrumentation for many reasons,” Wilson says. “The first of these is that we receive a high level of support from both Nortek’s UK and Norwegian offices – we can be certain that if there is an equipment problem or if we have a technical query, our issues will be dealt with very quickly, even ‘after hours’.”

Partrac has also found Nortek’s ADCPs to be highly reliable and easy to work with.

“We find the quality of the products exceptional and the instruments are also user-friendly; they are very intuitive to use,” Wilson says.

Nortek has been an innovator since its creation in 1996, constantly developing new acoustic technologies and solutions that enable users to measure water movement ever more accurately. Wilson says he has experienced first-hand how this culture of innovation translates into practice.

“We consider Nortek’s instrumentation design and technology very progressive and adoptive of the developments in information technology in general,” he says.

“People at Nortek provided critical support in optimizing the programming solution”

Oceanographic deployments in harsh environments are, by their nature, a risky business, but those risks need to be minimized. Sensors and ancillary equipment must be robust, reliable, and easy to retrieve. Lost or faulty sensors mean lost data, and potentially lost business for companies like Partrac, who are required to deliver accurate data to their clients on time.

This was Partrac’s first deployment of the Signature 250 in the configuration used, so Nortek ensured the team was well supported with advice, as well as channeling feedback to Partrac from others operating in similar environments.

“The people at Nortek provided critical support in optimizing the programming solution for the instrument and providing advice on mooring solutions. They were able to put us in touch with other users who have used the same equipment and mooring configuration, providing valuable insight into the robustness of the system and the data achievable,” says Wilson.

Ocean tech collaboration key to offshore wind energy progress

Pete Wilson says he hopes his company’s work will help drive forward the offshore renewables sector in Europe. “The data and the advice we provide is critical in both the early-stage site feasibility and consenting stages and later during the engineering process,” he says.

Technology partners such as Nortek have a key role in supporting the exploitation of new sources of renewable energy – their collaboration is critical to the future success of the wind industry.

Floating wind is a niche technology, but it is quickly gaining traction. The GWEC estimates floating wind generation capacity globally could rise to over 6 GW by 2030, compared to less than 0.07 GW in 2019. And growth could be a lot higher than that if development costs decrease – a likely prospect, as the efficiency and size of turbines increases and companies gain more experience of building floating windfarms.