Accurate navigation for a compact ROV supports safer underwater inspection, search and maintenance

- User stories

Synopsis

Challenge

Tethys Robotics’ goal was to build an autonomous underwater drone capable of being deployed in rough water with currents of up to 2 m/s. It would need to be capable of high-accuracy positioning and inspection of its immediate environment in near-zero visibility. This required a very accurate underwater navigation solution.

Solution

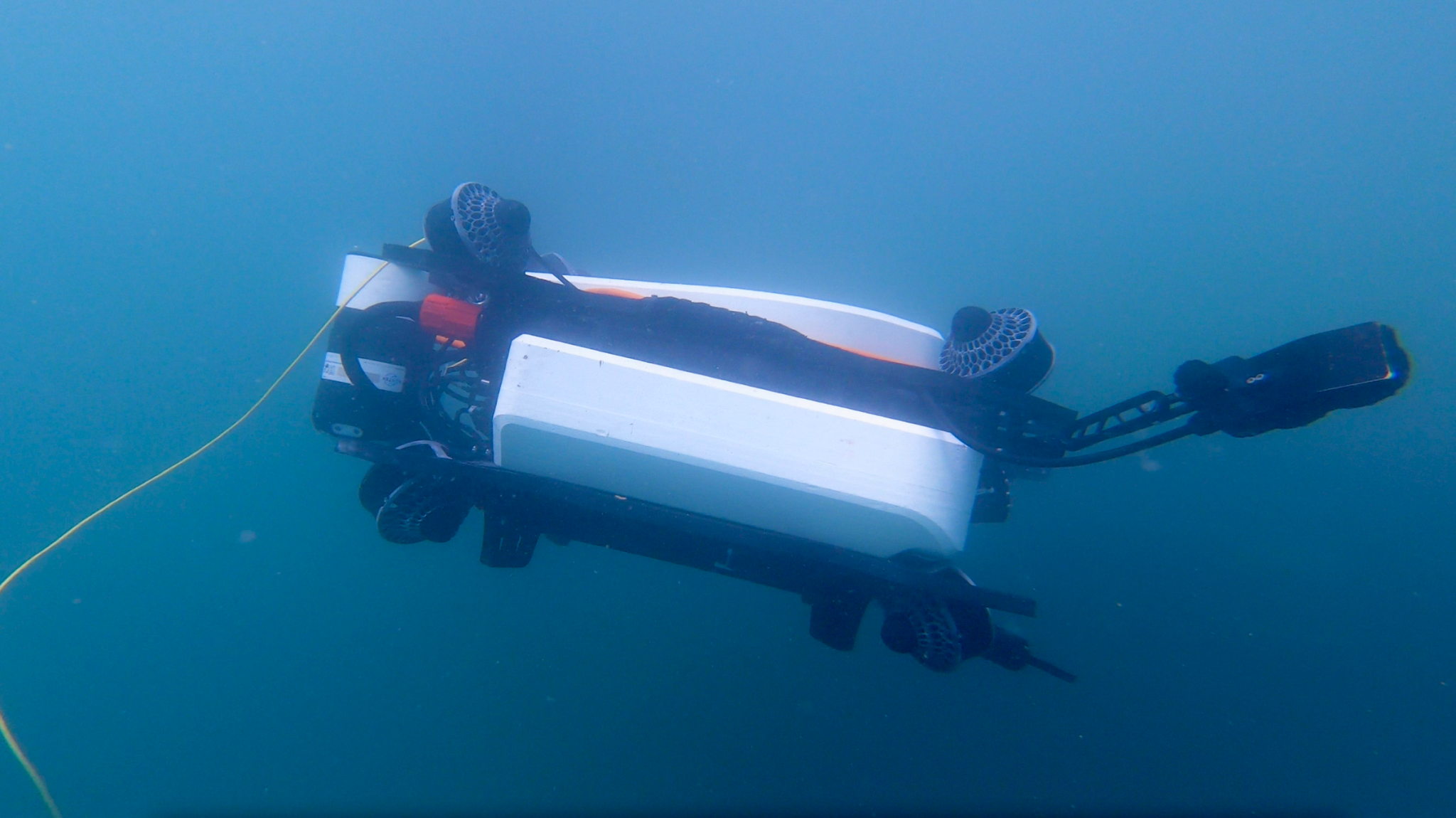

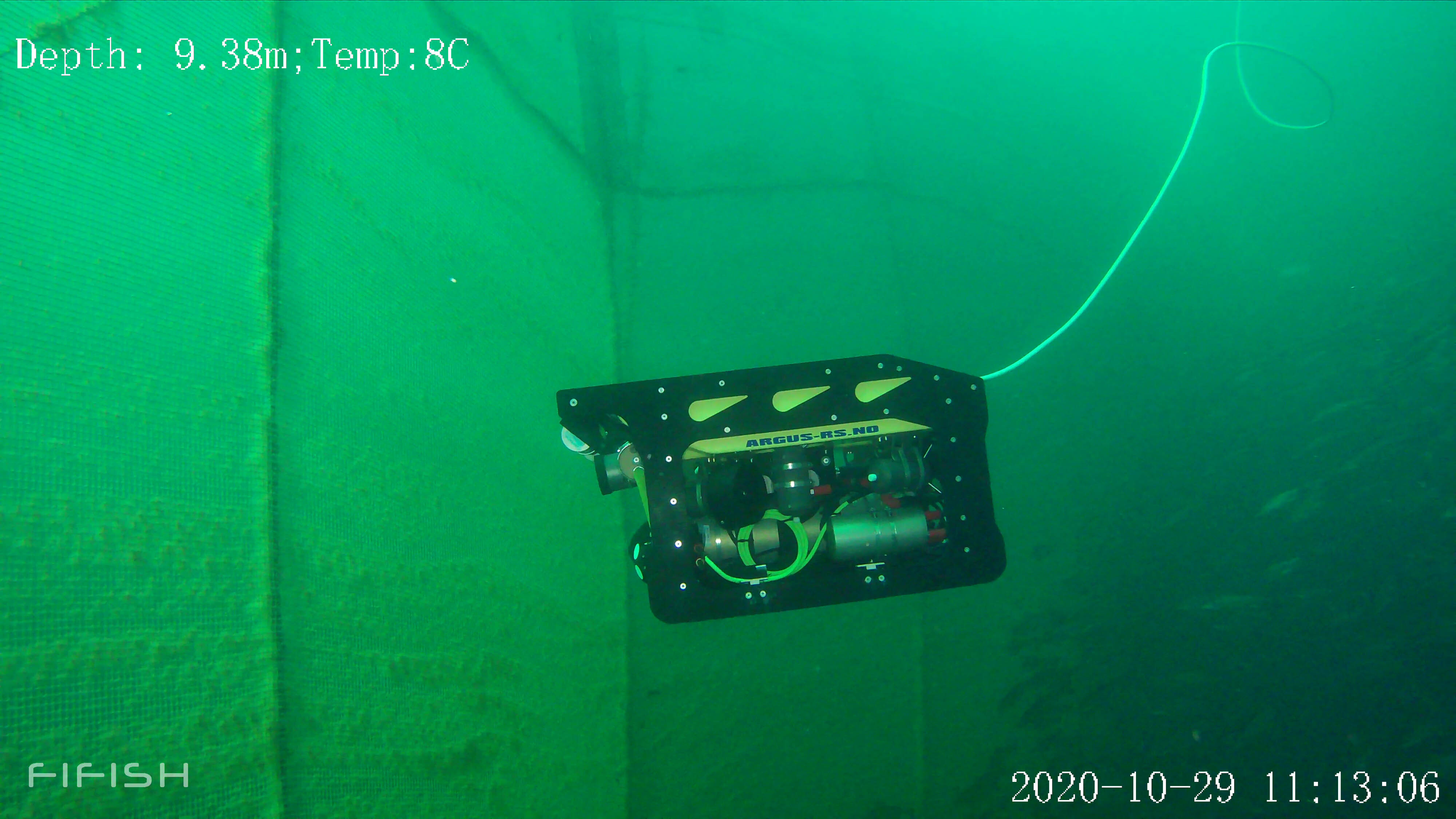

Tethys Robotics’ small ROV is equipped with a Nortek DVL that meets their specific requirements for achieving bottom tracking and current measurements in the most difficult conditions, securing navigational accuracy.

Benefit

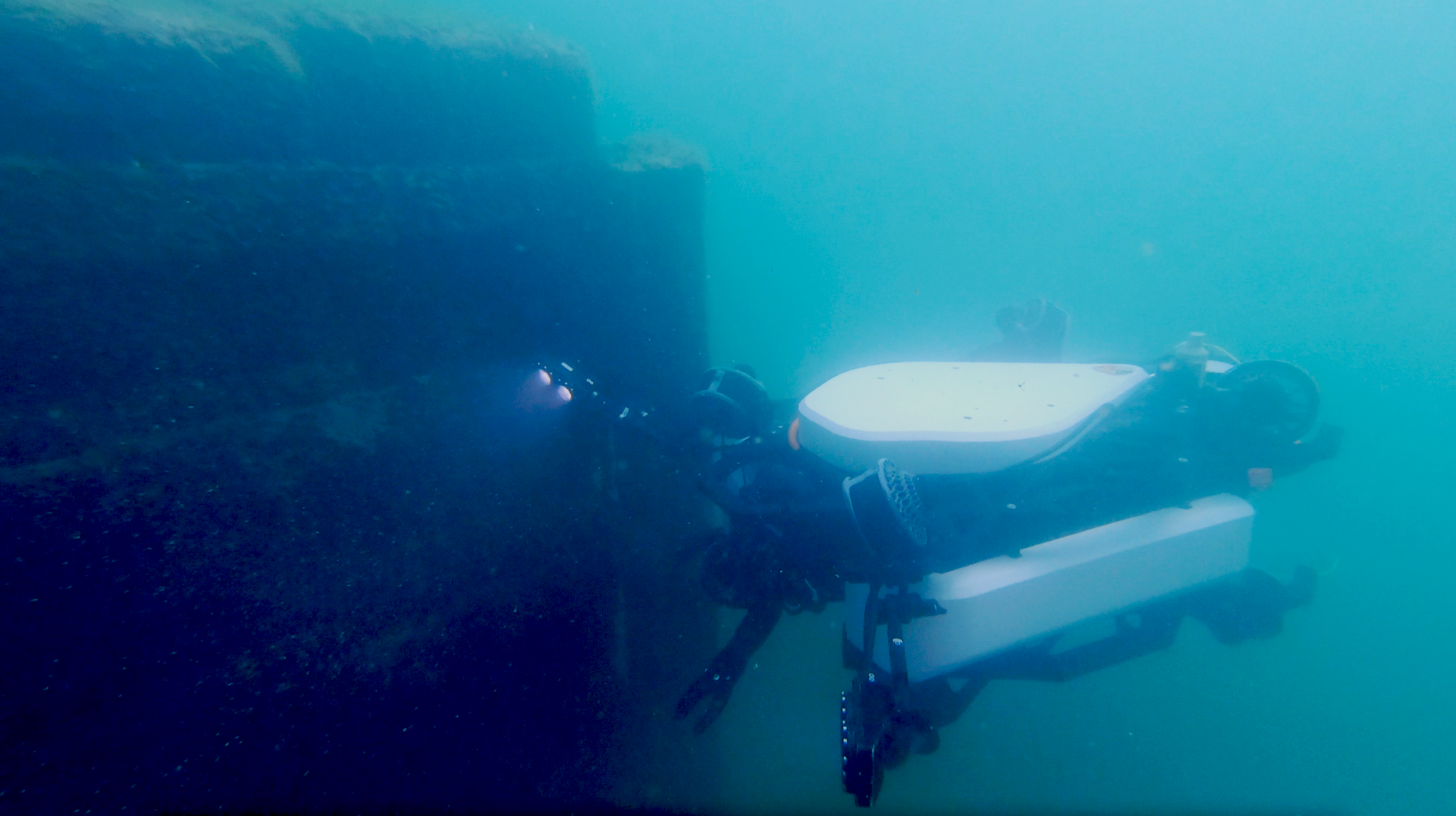

Tethys Robotics provides a safe alternative that does not expose human divers to dangerous situations. Using an ROV with a DVL also helps in exceeding the depth and dive-time limits of divers, while providing more precise and accurate surveillance and inspection.

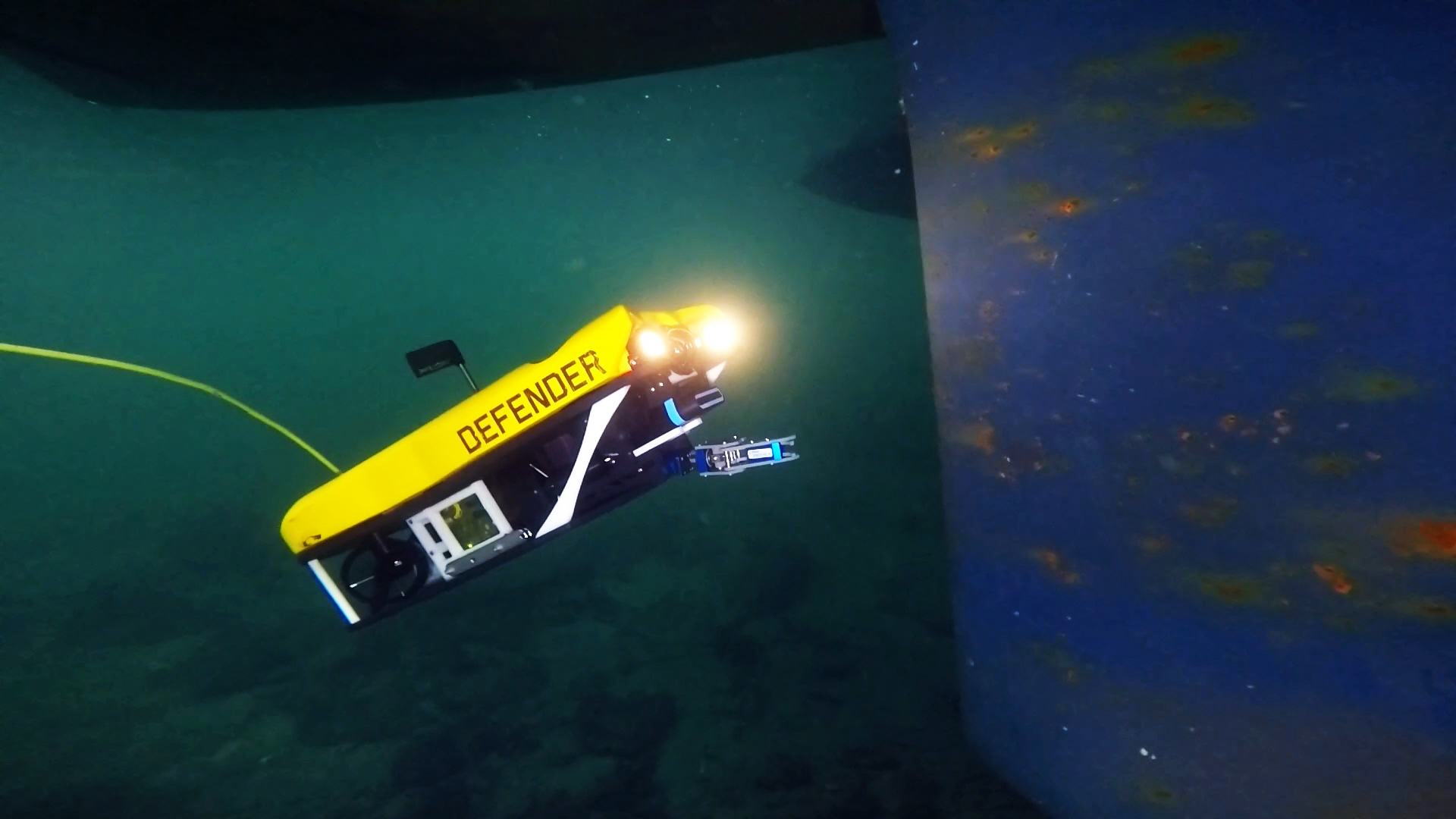

There are several technical challenges to operating an underwater robot in a lake or river, or offshore in areas of strong tides: the water is often cloudy or murky, making visibility poor, often with leaves and other objects floating or in suspension. The water can be fast flowing, and the bottom can be moving, with sediment, or small stones dragged along by the current.

There are significant challenges to maintaining accurate underwater navigation for vehicles operating in such conditions. Building an ROV that can operate successfully in rough conditions requires a range of sensor and control technologies.

Keeping an ROV stationary in a river in turbid conditions

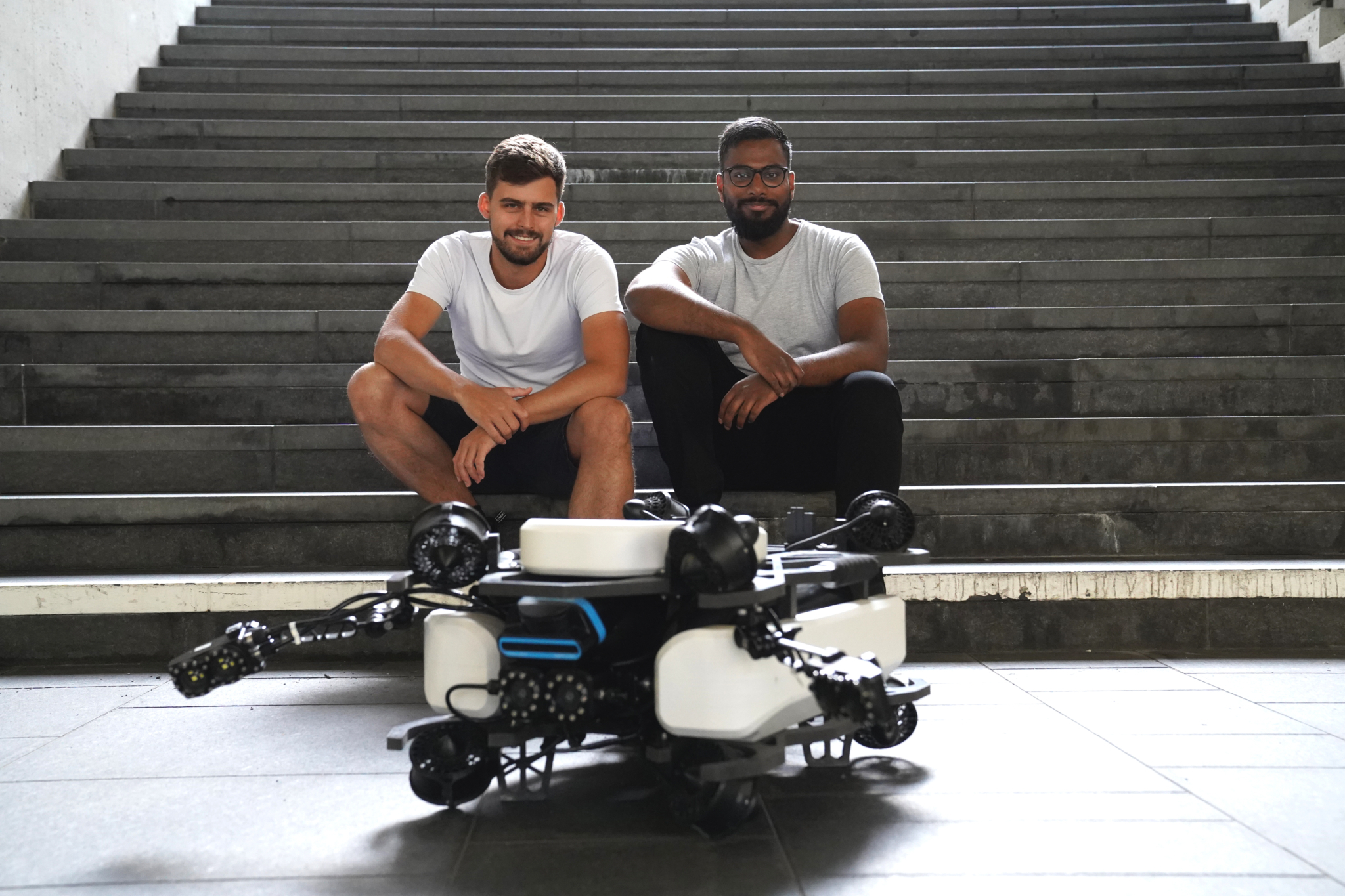

Jonas Wüst, now CEO at Tethys Robotics, set out to meet these challenges following a student research project at Eidgenössische Technische Hochschule Zürich (ETH Zurich), a public university in Switzerland.

“While doing our underwater robotics Master’s between 2020 and 2022, [we worked] to develop robust, reliable localization [navigation] software,” he says.

“The main work was to evaluate the individual [sensor] systems and then fuse them together in an appropriate way, providing centimeter accuracy and a high-frequency localization tool on the underwater robot so that the robot knows where it is and can hold [itself] stationary in a river under very turbid conditions,” Wüst explains.

Controlling an underwater robot in swirling currents

If this can be achieved it provides immense advantages to operators, as they can focus on controlling the robot relative to the stationary physical surroundings, without having to worry about trying to control it against swirling currents.

To meet these positioning and navigation needs for their ROV, Wüst and his team tested different DVLs from Nortek, with several frequencies and bandwidth within the sensors.

The DVL, or Doppler Velocity Log, is an acoustic sensor that estimates velocity in water relative to the bottom, using a long pulse along a minimum of three acoustic beams, each pointing in a different direction.

Achieving bottom tracking for ROVs near a moving riverbed or sea floor

“Our main challenge was to find a device that can handle a moving seabed (due to moving sediment), but we also needed the ability to work very, very close to the sea floor or the riverbed,” Wüst adds.

When Nortek then developed the DVL 500 Compact – a lower-frequency 500 kHz DVL in a small form factor – this was a great match for the requirements of the small ROV the team at Tethys Robotics was working on.

“The DVL 500 Compact enabled us to penetrate turbid water – including leaves flying by – much more easily and reliably, and therefore the signal consistency was much better,” Wüst says.

Nortek’s Cristobal Molina, the Senior Sales Engineer working on the project, explains: “The benefit for Tethys Robotics of the DVL 500 Compact was the penetration through the bottom, river or lakebed. Lower-frequency DVLs penetrate more in such scenarios. With the help of Tethys Robotics we tested our theory that it is also better for moving bottoms in this specific application.”

Typically, high-performance, lower-frequency DVLs have been physically larger, making them difficult to use on smaller vehicles.

The DVL 500 Compact represents the latest generation in survey-grade DVL technology. By combining the convenient size of the higher-frequency DVL1000 with the superior bottom-tracking range of traditionally larger 500 kHz systems, the DVL 500 Compact provides developers of small robotic systems with a reliable, high-performance solution for aiding underwater navigation and control.

An underwater navigation solution supplemented with additional sensing capability

The Tethys underwater robot uses a virtual headset and tethered control, which allows the ROV pilot to be fully immersed in the underwater environment, but their developers have also added much greater sensing capability.

Wüst explains that in many deployment scenarios, visibility is normally not much better than 10 or 20 cm.

“So, we combined cameras with sonar vision, and we also have an entire AI-powered pipeline on the sonar images to reconstruct features, enabling an easy-to-understand 3D image of the surveyed area.”

“The underwater navigation solution with the DVL means that the robot knows where it is, but it also needs to sense the surroundings … That’s equally important for this application.”

Autonomous mapping of submerged infrastructure in strong currents and poor visibility

Their work with the underwater robot has attracted a lot of attention.

“Tethys Robotics is an invaluable partner for developing underwater drones with unique capabilities, such as for autonomous mapping of submerged infrastructures in strong currents and poor visibility,” says Kai Holtmann, Deputy Head of the Swiss Drone and Robotics Centre.

“Their innovative approach allows inspection and exploration works to be carried out at lower cost and, most importantly, without putting divers at risk.”

Good localization and mapping simplify underwater ROV inspections

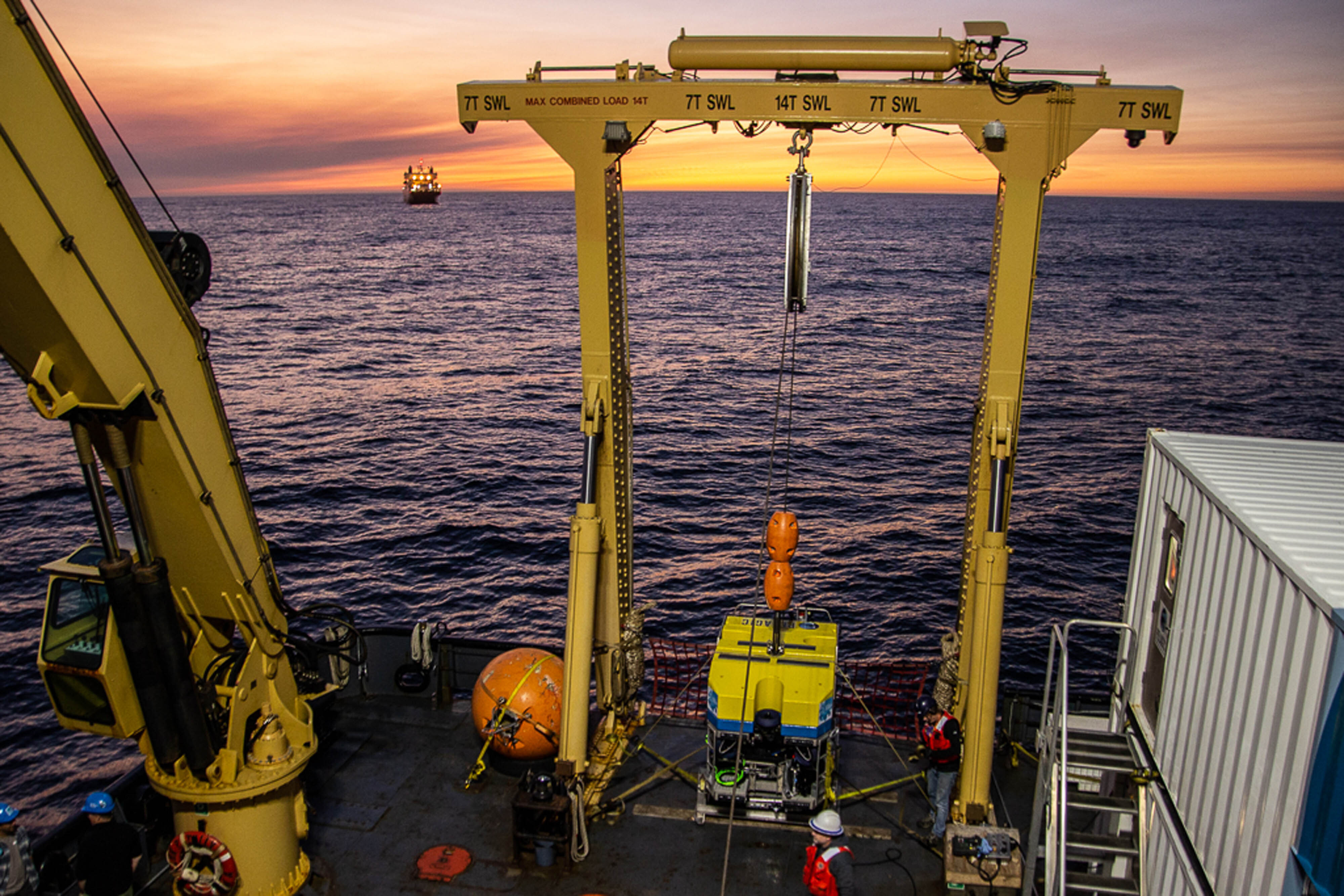

The success of the unit has opened up a whole new world of applications.

“We are now aiming for applications where we can replace divers, especially in dangerous situations. We recently had our first test at a hydroelectric power plant, where the underwater robot had to hold its position relative to the ground in a river flowing at up to 1.2 m/s. It was quite a milestone to see it used in this application, and how easy it is to do inspections if you have good localization and mapping,” Wüst says.

“You don’t need to be a fighter pilot to steer the drone.”

Wüst also emphasizes that the quality of the images also increases quite a lot compared to using a diver.

“We can look at the structure in detail and collect all the acoustic data from the sonar as well as the images from the camera if the visibility is sufficient. And then we can reconstruct everything to have an accurate 3D model, which is quite valuable for the inspection afterwards.”

His team is trying to provide an end-to-end solution that will help the user see whether the structure that has been inspected needs maintenance, or if it can even support a predictive maintenance process.

The ability of the ROV to hold its position helps search and inspection

“We can guarantee the accuracy of the inspection path for the ROV, so that you can be sure that you have seen everything,” Wüst says. The ability of the ROV to hold its position and know exactly where it is means that search and inspection grids can be followed very precisely.

The technology promises significant benefits for the reliability and safety of important infrastructure.

“Wherever you have submerged infrastructure, good reliable inspection is key.”

There are also promising applications for research on submerged structures. “We’re in talks with archeological teams here in Switzerland,” adds Wüst.