Fulfilling the changing needs of the subsea vehicle market

Nortek’s DVL product line is marking its fifth year in the world of marine robotics. Integrators turn to them seeking high-performance and reliable navigation, ranging from commercial-grade ROV/AUV operations to groundbreaking scientific research platforms.

Here is a review of some of the reasons behind the success of the product line, and where the field of subsea navigation is heading.

Developing a novel DVL solution

Development of Nortek’s DVL product line made strides during the 2014–2016 oil and gas downturn. The offshore industry was being squeezed to achieve more with less, meaning demand for large Work Class ROVs was replaced with a demand for smaller, multi-purpose ROVs. Expectations of their capabilities remained, meaning high-performance survey and navigation sensors became a central focus. Most commercially available DVLs at the time were not suitable for smaller platforms due to their size and weight, something that had not been an issue for Work Class ROV systems.

Nortek set out to use its decades of expertise in Doppler subsea measurements to make something specifically for small vehicles. The goal? Provide greater range and survey-grade performance in a drastically reduced SWaP (Size, Weight and Power) footprint. This had to be done at a cost which would enable wider use of sophisticated navigation without sacrificing the accuracy required for survey or autonomous navigation. The new Nortek DVL supported the offshore industry’s requirements during the downturn, but also awakeneddevelopment possibilities for a new breed of intelligently controlled, compact ROV and AUV systems. Such vehicles are now becoming more common across the survey, inspection and defense markets.

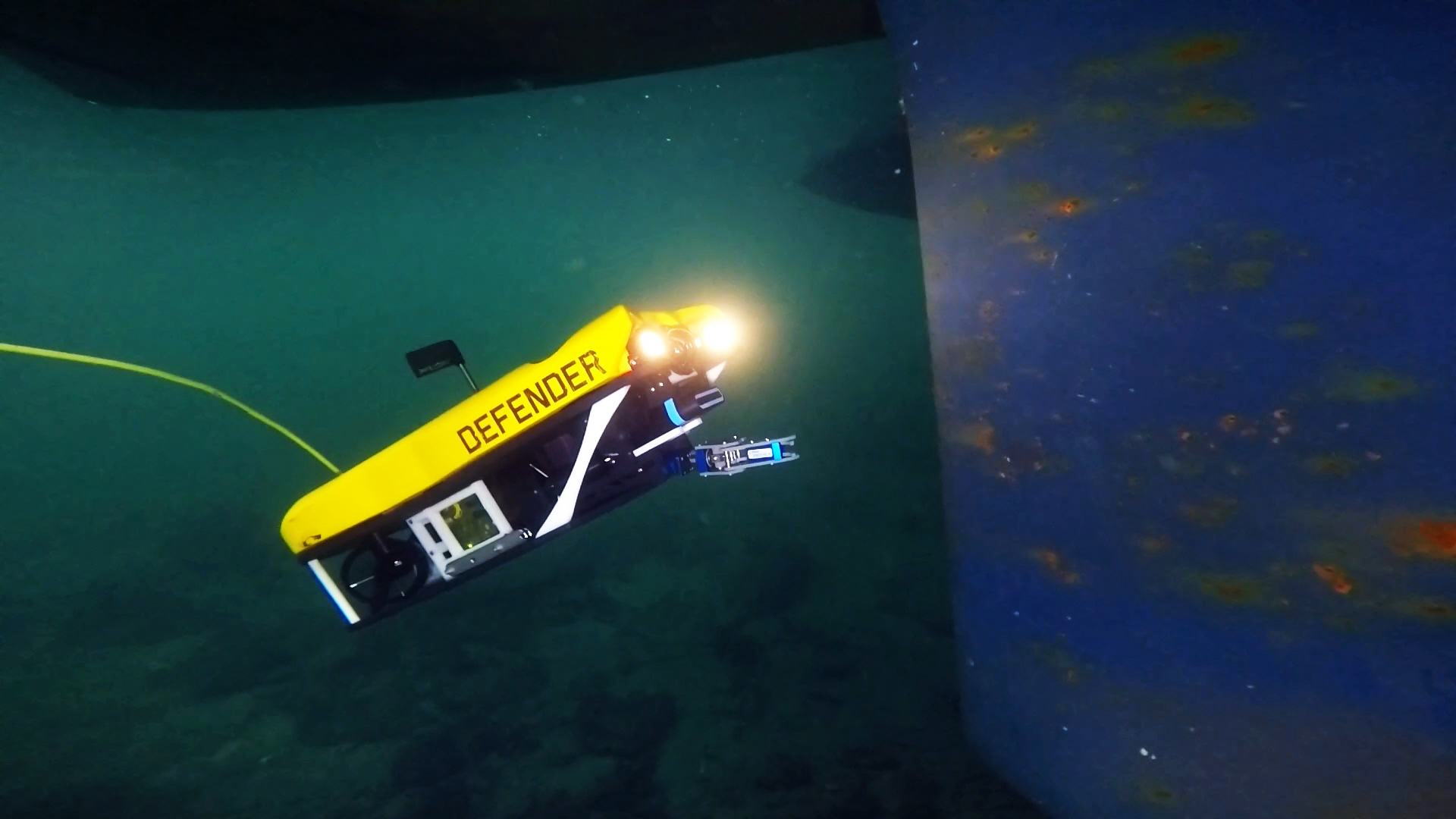

Marcus Kolb, Chief Technology Officer at VideoRay, a global leader in small but powerful ROVs, recalls: “Not surprisingly, we weren’t getting the performance we needed from any DVL manufacturer. The VideoRay Defender is a very powerful and compact system with seven 1 hp thrusters and a 1.5 kW power converter, all in close proximity to the DVL. Nortek stepped up, learned about our unique challenges and figured out how to make a good solution into something that exceeded the requirements and our expectations. We continue to work with Nortek on improvements and have delivered several 4 km rated DVLs that are performing very well and drop into the Defender without modifications.”

Designing for challenging situations benefits all

As small vehicles become more capable and assume work previously done with larger vehicles, large ROVs push forward into more complex missions and greater autonomy, demanding more from their navigation systems. Swapping older units with drop-in replacements which feature the most modern processing allows commercial survey companies to employ more advanced autonomy and station-keeping without overhauling their entire navigation system.

This key benefit is in part due to tight coupling between DVL and Inertial Navigation Systems (INS). “Tight coupling” is a technique that improves synchronization between DVL velocity and INS measurements. This is primarily achieved by providing time-of-validity readings for bottom-track velocity estimates, which in turn improves overall navigation system performance. This technique has now become a standard, and most high-performance INS now require DVLs to provide this.

Further, for these vehicles performing complex, long-term missions in deeper waters and changing conditions, the addition of simultaneous current profiling allows users to monitor environmental conditions in real time when operating at dynamic sites.

Customization delivers fit-for-purpose vehicles

Supporting innovation means responding to novel requirements. This leads to unconventional designs – from deconstructed DVLs to imaginatively arranged sensor heads – which have pushed DVLs beyond their normal performance capabilities and ushered in an era of specialized, purpose-built vehicles. These vehicles allow jobs to become more efficient, safer and often more cost-effective. A partnership approach in design means sensor manufacturers are headed where the industry is going, elevating the ease-of-use and making vehicles more commonplace tools, thereby expanding the market.

Challenges encountered in demanding custom designs inevitably inform technological advances for COTS (Commercial off the Shelf) products. One such situation is ensuring consistent performance when sensors and electronics are in close proximity inside small vehicles. The refinements that make this possible have resulted in versatile and reliable DVLs, benefiting vehicle manufacturers.

“We turned to Nortek for our subsea navigation needs because of the accurate, reliable and repeatable data provided by the system. Coupled with the small form factor and integration support from Nortek, this makes it a perfect solution for VALOR,” points out Scott Gray, Regional Manager at Seatronics.

The future of subsea navigation

Moving into an era where remote operations and autonomy will play a significant role in how we work offshore, subsea navigation is once again at a crossroads. There is a growing requirement for long-endurance, uncrewed survey capabilities. These require highly accurate navigation over long distances, coupled with system reliability, low power consumption and redundancy.

On the other hand, there is a drive to make subsea navigation more accessible. This relates to micro-ROVs/AUVs and even divers, who need simple, economical and compact navigation. As before, the theme of achieving more with less persists, and the onus is on sensor manufacturers to develop solutions that can deliver on these requirements.

While divergent in technical requirements, cost and form factor, these trends converge on the path of institutionalizing these tools in operations, inspection, construction and research. Development of sensors like the DVL500 Compact or the coming Fusion DVL1000 is part of a drive to allow vehicles to become more capable at any size and cost. As we look towards decarbonizing the offshore industry, extending autonomous/uncrewed mission durations and enabling operations in coastal and deep water, it is critical to improving the viability of such technologies.

By Rory Findlay,

Navigation Business Development Manager, Nortek