A tailor-made buoy makes the deployment of Signature ADCPs even easier!

The buoy is cylindrical with a slight conical shape. This means that the buoy will maintain a vertical orientation, even when exposed to strong currents and wave action, which vital for good data.

The Signature subsurface buoy is constructed from two identical halves, with internal pockets that fit the Signature250/500 and either a single or double battery canister. Just four bolts are needed to hold the two halves together, and no screws or bolts are needed to keep the instrument and battery canister in place inside the buoy.

Preparing the Signature buoy for deployment is quick and easy.

There are no magnetic parts in the buoy, and this means that it will not affect the Signature’s compass.

The bottom part of the Signature buoy has a removable anchor plate with an arrangement that makes it very easy to attach the mooring rope.

See this video on how to set up and deploy the Signature buoy.

Swift and easy assembly of buoy and ADCP

All of this means that the assembly of the Signature buoy, an external battery canister and the Signature250/500 can be done in less than ten minutes. You save valuable time in the field while at the same time ensuring trustworthy data once the buoy is deployed.

The Signature buoy simplifies the deployment of Signature250 and Signature500 ADCPs.

Improved data quality and reduced ship time

The fact that the buoy is tailor-made for the Signature instruments further guarantees that the deployment can be done exactly the same way every time. Hence, interpretation of the measured current data does not depend on changing buoy concepts.

With the Signature buoy, the whole mooring with the ADCP becomes one coherent setup and design, rather than a collection of parts from various sources. This ensures improved data quality and saves expensive ship time in the field.

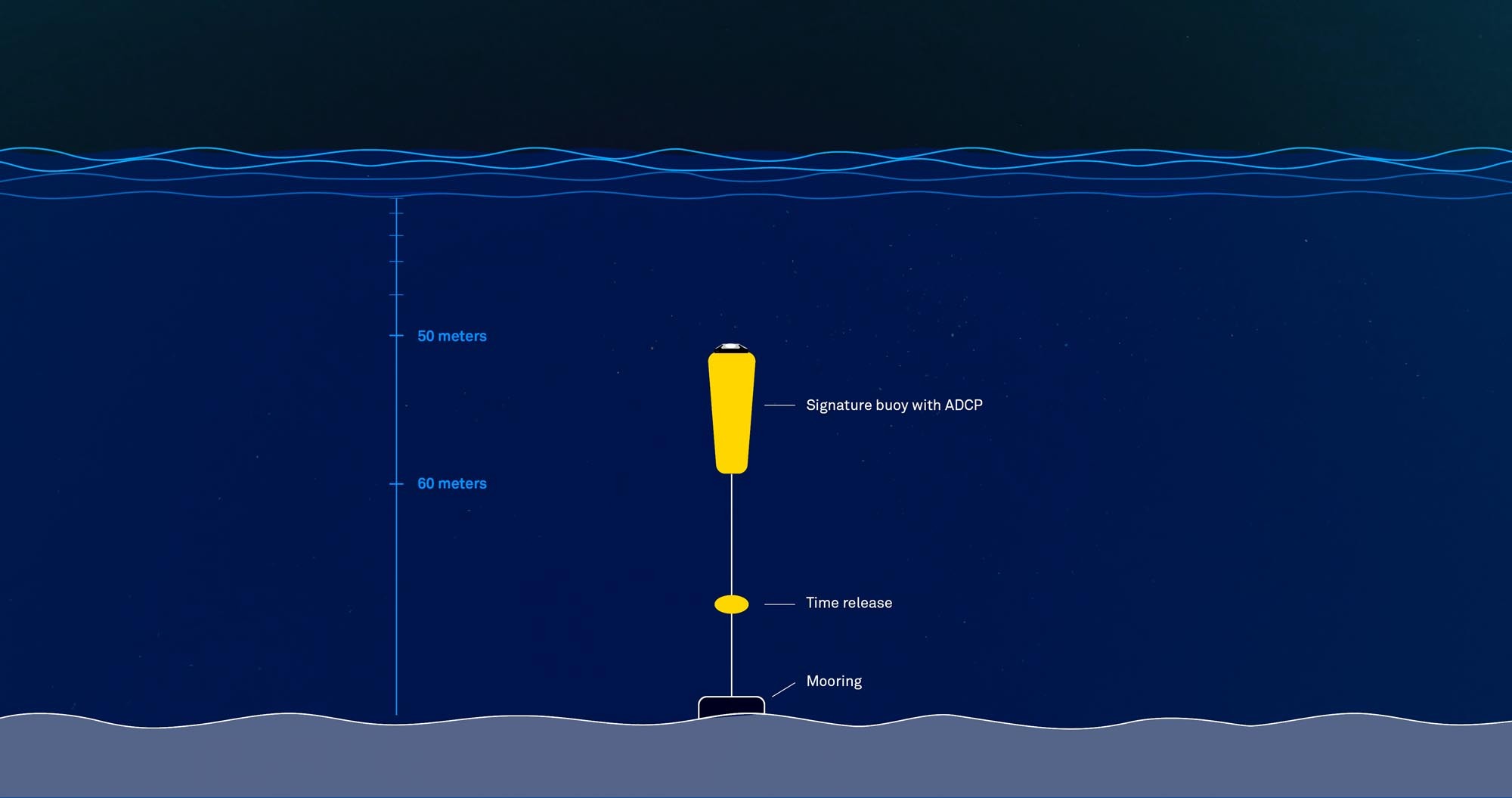

Deploying a Signature buoy requires a time release and a mooring.